Calculator

Ensuring the quality of the manufactured parts by applying effective controls, performed with reliable, fast and easy-to-use measuring equipment is a delicate task. Creaform’s calculator measures quickly and efficiently all savings associated with Creaform’s 3D scanners product offering.

First-Year Savings Calculator

This simple tool will provide an estimate of the first-year savings, following a Creaform 3D scanner investment.

Calculate

Information

Results

Cost Prevention

Direct Labor SavingsRefers to the reduced manufacturing labor – Always use direct wages + benefits (27.5% average benefit costs)

Total hours saved

Cost per hour ($)

Rework and scrap savingsCost of quality issues that required additional manufacturing labor and cost to rectify the problem. Includes the cost of quality issues that cannot be reworked. Top performers are around 0.6% business revenues. Worst performers are around 2.2% of business revenues and sometimes more.

Annual sales ($)

Cost waste, scrap & rework (%)

Floor Space ReductionPrices per square foot to build manufacturing facilities often vary. Average cost may vary from $2100 per square meters or $200 per square foot up to $6400 per square meter or $600 per square foot. These savings are often realized when an automated solution produces more than a manual operation.

Floor space reduction

Select your size

Cost per ft2 ($)

Cost per m2 ($)

Employee RetentionThese savings are often realized when automating difficult working conditions. On average it costs $4129 and 42 days to fill an open position. The cost to hire increases proportionately based on the duration of the search.

Average hiring cost ($)

Position saved

Average training time

Labor cost per hour ($)

Revenue Growth

Capacity GainRefers to the increase in revenues for the company due to the adoption of a 3D scanning solution.

Additionnal pieces measured

Price per part ($)

Margin on each part (%)

Customer RetentionCost of sales and marketing divided by the number of new customers acquired.

Customer aquisition cost ($)

Number of customer retained

Information

Thank you for your interest in Creaform! Please fill out the form below.

The more we know about you, the better we will be at providing you with relevant answers. Our team will contact you very soon.

Results

HandySCAN 3D | BLACK Series is the fastest portable metrology-grade 3D laser scanner on the market, offering the highest measurement rate and accuracy available. It’s ideal for product development and quality control.

Total saving per years

HandySCAN 3D Black

Total saving per years

| Cost Prevention summary | |

| Revenue Growth summary | |

| Total saving per years |

HandySCAN 3D Black

Applications cases

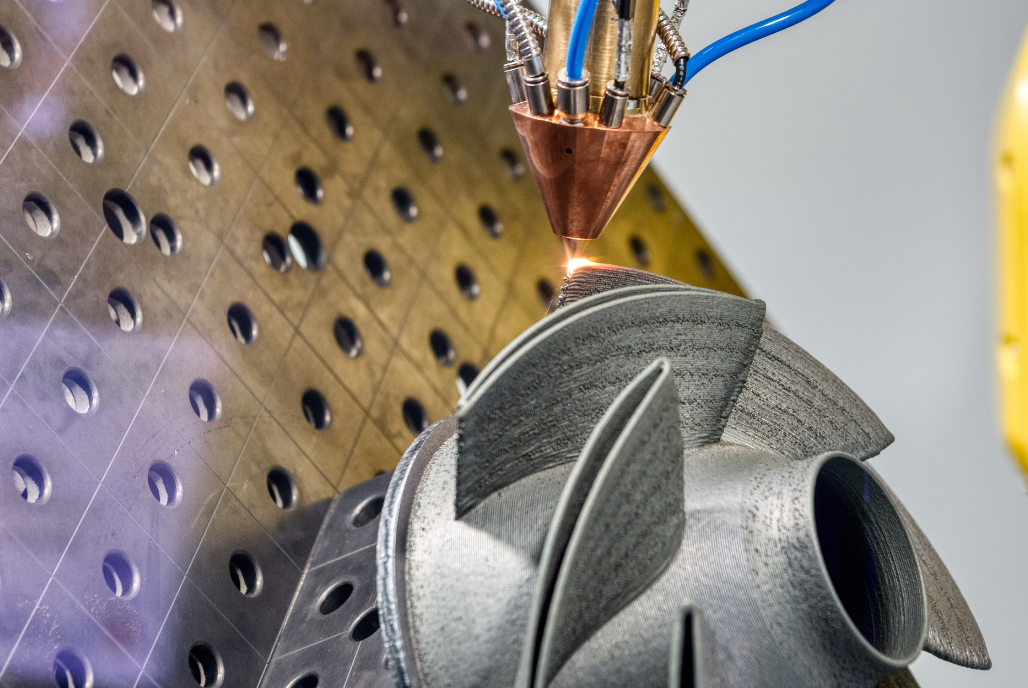

Developing, manufacturing, and inspecting a casting of superior quality in less time

Applications: Quality control and Quality assurance

Industries: Aerospace, Manufacturing

Power turbine component analysis - 3d scanning

Applications: Quality control and Quality assurance, Maintenance, Repair, and Overhaul

Industries: Power Generation

Accelerating the iterative process in tool design with intermediate quality checks

Applications: Quality control and Quality assurance

Industries: Manufacturing

HandySCAN 3D Black

The HandySCAN 3D™ line-up is the reference in portable metrology‑grade 3D scanner. Optimized to meet the needs of design, manufacturing and metrology professionals, the BLACK Series provides the most effective and reliable way to acquire accurate 3D measurements of physical objects anywhere.

See more| Suggested product |

Results

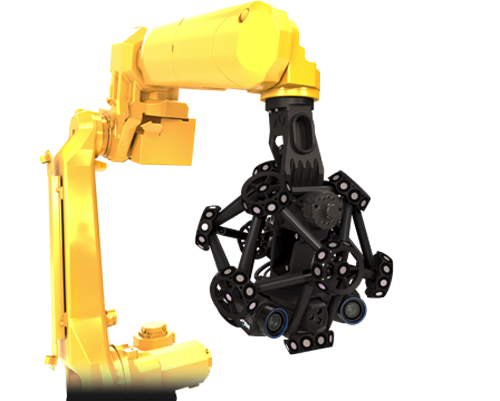

The most complete 3D scanners for metrology-grade measurements on all materials, MetraSCAN 3D is a powerful inspection solution that is insensitive to instabilities and harsh environments.

Total saving per years

MetraSCAN 3D

Total saving per years

| Cost Prevention summary | |

| Revenue Growth summary | |

| Total saving per years |

MetraSCAN 3D

Applications cases

3d scanning in oems [automotive] and aftermarket sectors

Applications: Quality control and Quality assurance

Industries: Automotive/Transportation, Manufacturing

Tool testing and adjustment – moulds, jigs, frames and presses

Applications: Quality control and Quality assurance

Industries: Automotive/Transportation, Manufacturing

First article inspection – geometric elements, freeforms and reflective surfaces

Applications: Quality control and Quality assurance

Industries: Automotive/Transportation

MetraSCAN 3D

The MetraSCAN 3D optical CMM scanner line-up is specifically designed for manufacturing and metrology professionals who do not want to compromise on quality or efficiency. It can withstand any production environment, including shop floor vibrations, part movements and environmental instability—all while accelerating 3D measurement workflows. This optical CMM scanner has been engineered to perform highly accurate and repeatable metrology-grade measurements and 3D geometrical surface inspections.

See more| Suggested product |

MetraSCAN 3D-R

| Suggested product |

Applications cases

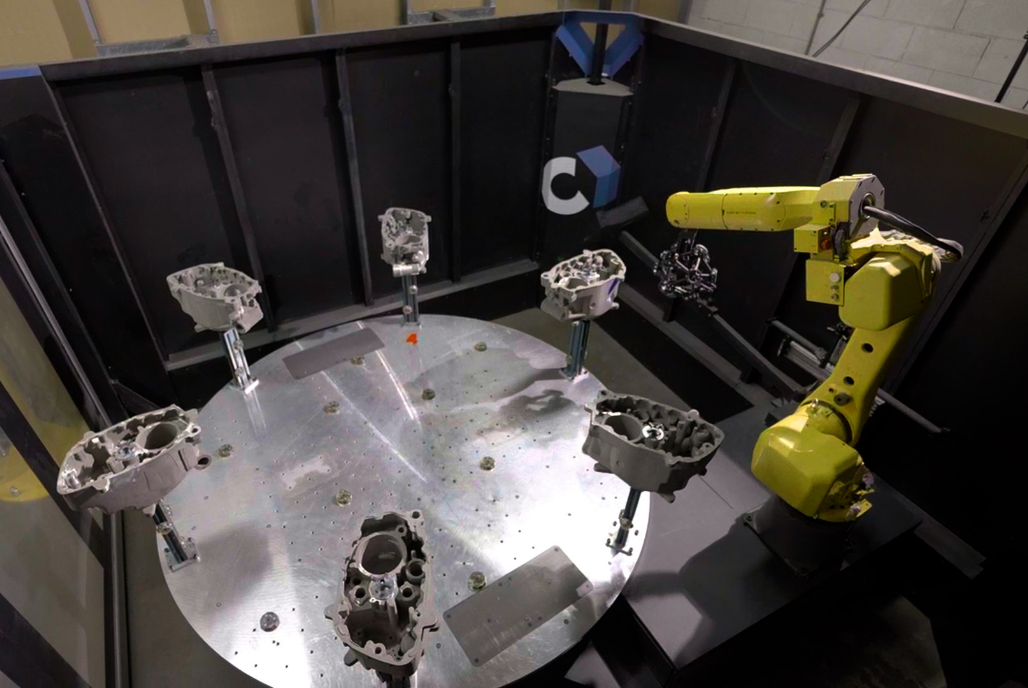

How can automotive part manufacturers improve productivity, perform more inspections faster and with more information

Applications: Quality control and Quality assurance

Industries: Automotive/Transportation

Automated quality control: a key strategy for e-car manufacturers to speed up their throughput

Applications: Quality control and Quality assurance

Industries: Automotive/Transportation, Manufacturing

Automated 3d scanning and inspection of high-precision stands

Applications: Quality control and Quality assurance

Industries: Automotive/Transportation, Manufacturing

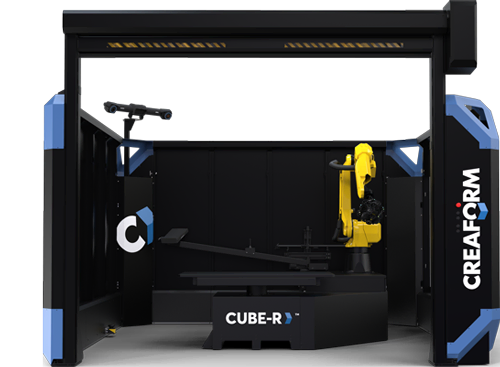

CUBE-R

The CUBE-R™ leverages the power of the MetraSCAN 3D-R in a high-productivity industrial measuring cell that has been designed to be integrated into factories for at-line inspections. Compared to traditional CMMs, the CUBE-R is much faster, providing a gain in productivity and better efficiency.

See more| Suggested product |